Shaftless Spiral Conveyor

This type of equipment has no central axis interference and can transport easily wound materials. With special lining board inside, the machine can work at high temperature.

Description

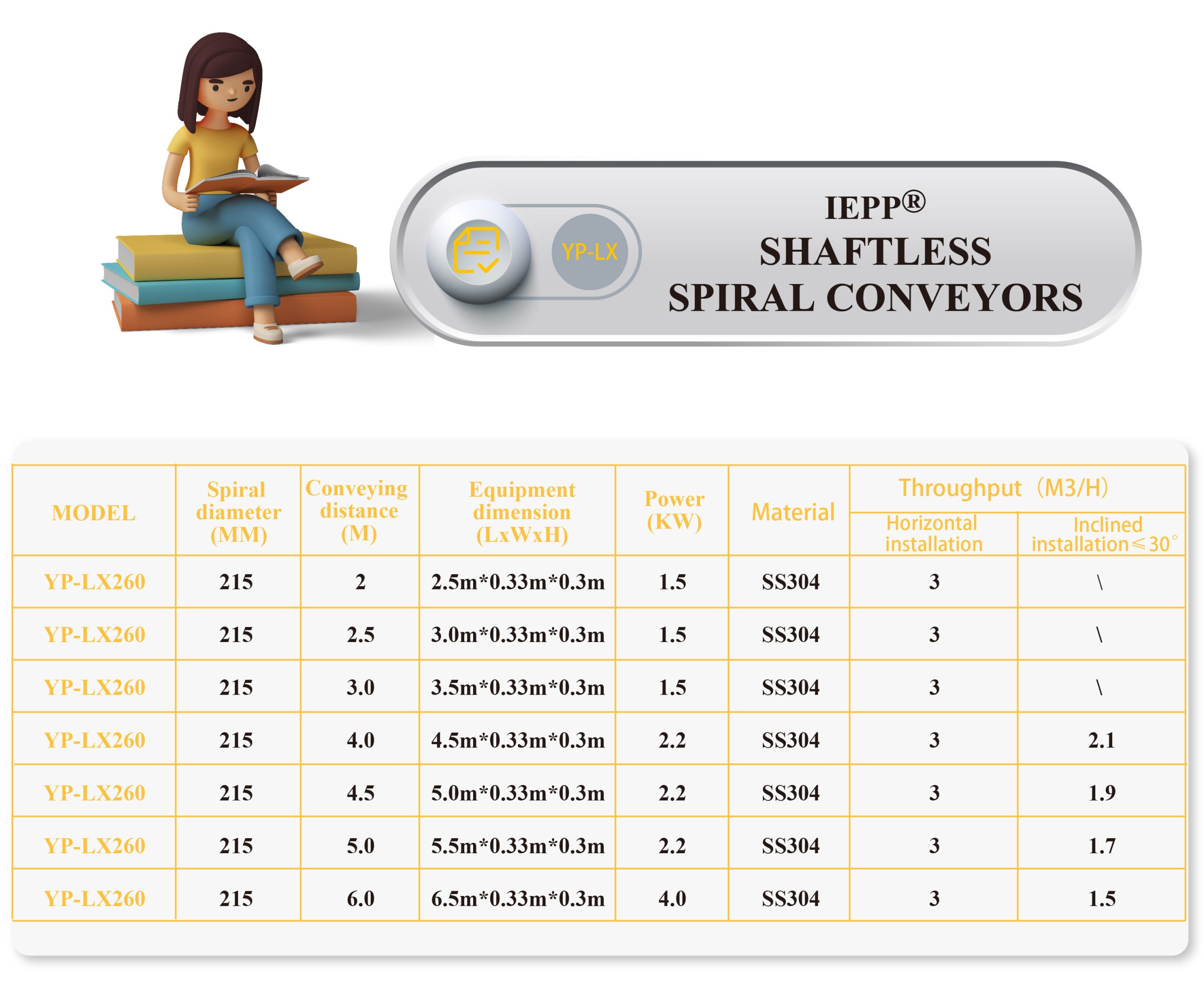

IEPP® horizontal and inclined shaftless spiral conveyor – with a simple construction – are an extremely reliable conveying option. The conveyor shell is made of 304 stainless steel, which is corrosion-resistant and durable.

The spiral is made out of special steel which has a very high tensile strength. IEPP® shaftless spiral conveyors are designed for the transport of otherwise difficult to handle materials, such as municipal dewatered sludge, wastewater screenings, grit, industrial sludges and other sticky, viscous, stringy materials.

Compared to traditional conveying methods, shaftless screws allow for higher fill rates and lower rotational speeds, resulting in less wear, less maintenance and less downtime. Eliminating the central axis improves fill rates, which means the solution is more cost-effective in terms of conveying.

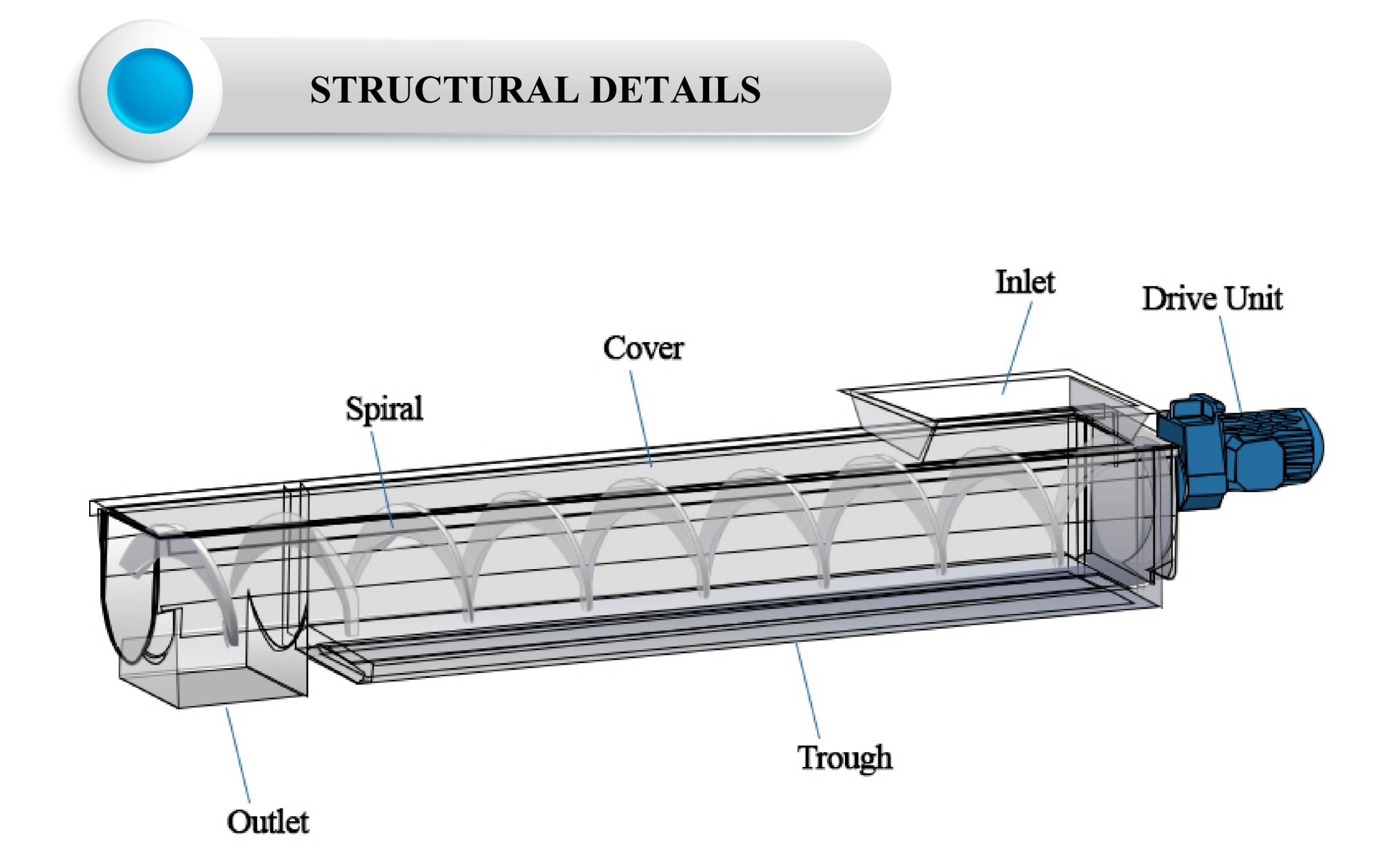

This product is mainly composed of drive device, head assembly, housing, shaftless spiral, slot liner, feed port, discharge port, cover, base, etc.

Driving device: The driving device is composed of motor and reducer.

Housing: The housing is u-shaped or o-shaped, with a rain-proof cover on the top. The material is 304 stainless steel.

Shaftless spiral: The material is carbon steel. The diameter of sprial can be customized according to customer needs.

Slot lining board: It is made of hard-wearing nylon.

Inlet and outlet: there are two types of inlet and outlet: square and round. The general inlet and outlet form is determined by the user.