Rotary Drum Screen

It can handle a large amount of water, and can be used for industrial water filtration such as raw water filtration in water plants, filtration of circulating cooling water, purification of wastewater.

Description

The IEPP® Perforated Rotary Drum Screen is an automatic, self-cleaning fine screen useful for applications from primary to membrane screening in municipal and industrial sewage treatment applications, designed specifically to protect secondary and tertiary wastewater treatment systems. The fine opening perforated media of the IEPP unit can effectively remove these materials in normal operation.

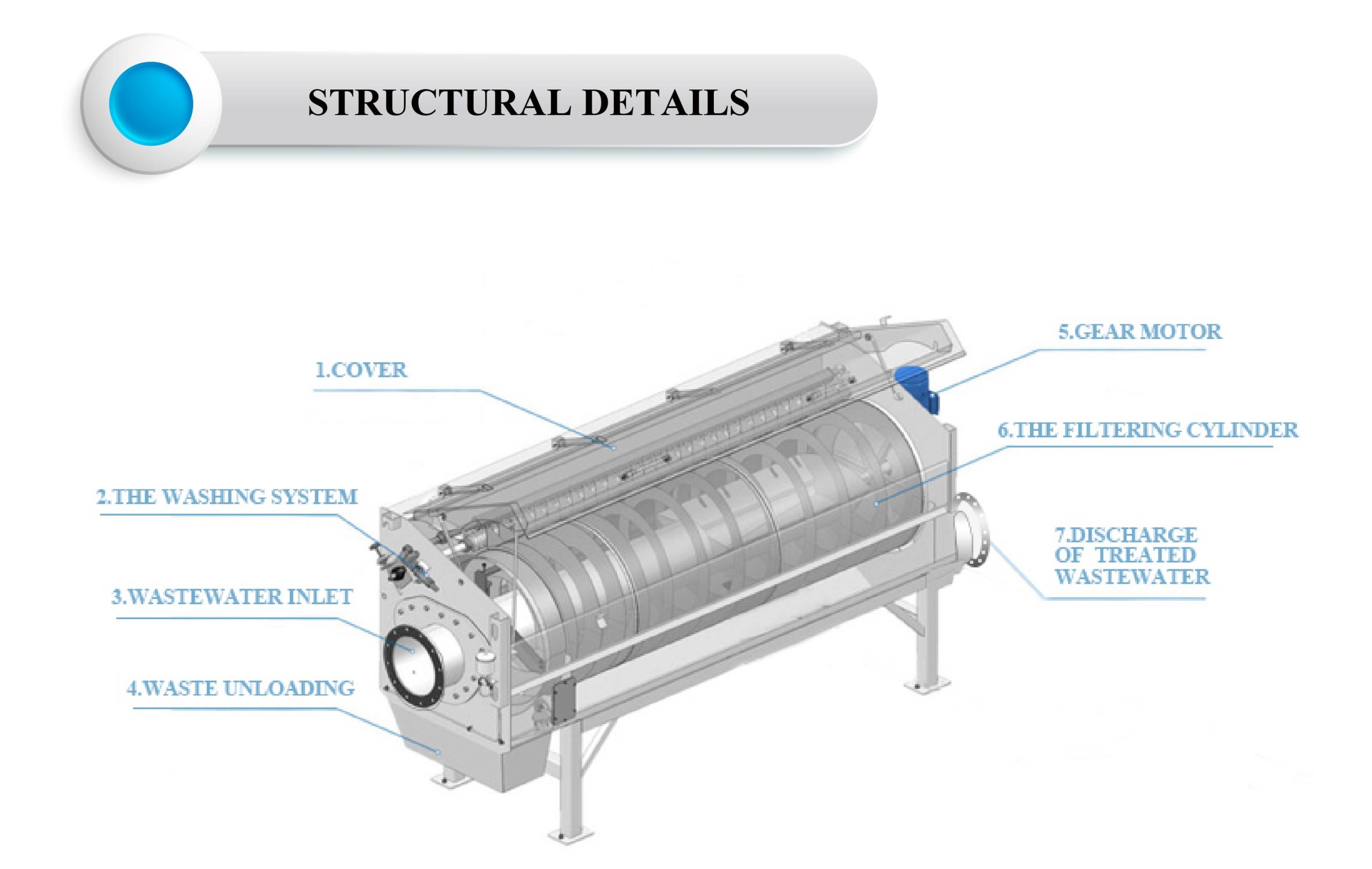

The perforated rotary drum screen consists of:

Drum of perforated media

External spray system

Flow distribution pipe

Support structure with trunnion wheels

Removable enclosures

Drum drive system composed of a gear motor and that eliminates chain maintenance.

Support structure and all wetted parts available in 304 or 316 stainless steel.

IEPP® Perforated Rotary Drum Screen Operation

Flow is pumped to the distribution pipe where it is directed onto the rotating drum. Wastewater passes through the openings in the drum while the captured screenings remain on the drum surface. Non-continuous flights inside the drum transport the screenings towards the discharge end of the drum. The screenings exit the unit and fall into a post screening device or a container. Spray water cycling is adjustable to ensure maximum performance.

1.COVER

A cover is provided for visual control of the process and ease of maintenance

2.THE WASHING SYSTEM

Cleaning the cylinder filter cloth is carried out by the rinsing nozzies that are supplied with water under pressure and placed on the outer surface of the cylinder in the upper area of the screen

3.WASTEWATER INLET

Untreated wastewater from the receiving manifold goes to the distribution device and then directly to the cylinder filtering surface

4.WASTE UNLOADING

An additional compacting press can be installed in the discharge area with a system for packing the waste into bags to prevent the spread of odours and reduce the volume of transported waste

5.GEAR MOTOR

The cylinder is driven by a gear motor for unloading waste from the screen and cleaning of the fitering surface

6.THE FILTERING CYLINDER

Cylinder filter cloth can be made of a triangular profile, perforated cloth or metal mesh depending on the type of wastewater and the required gap

7.DISCHARGE OF TREATED WASTEWATER

Treated wastewater is discharged by gravity from the baottom part of the screen