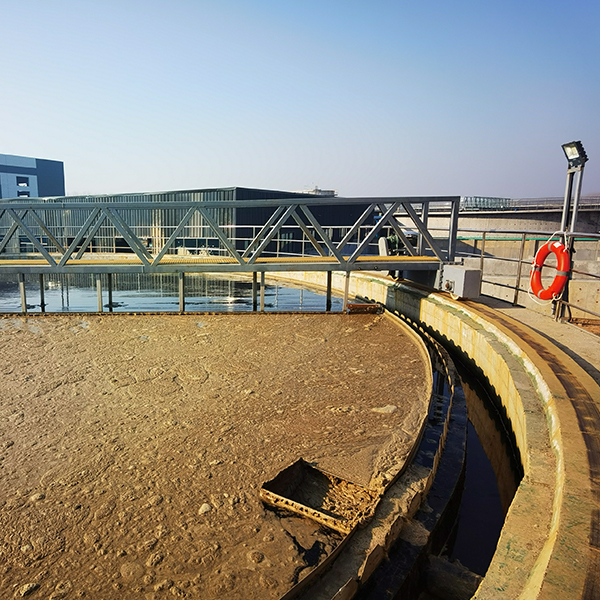

Peripheral Drive Mud Scraper and Suction Machine

The equipment can scrape mud, suck mud and scrape scum at the same time, with low energy consumption and large processing capacity.

Description

INTRODUCTION:

The scraper bridges for circular decanters manufactured by IEPP. have been designed to effectively extract the sludge and floats in primary or secondary decanters. The bridge is supported by a civil engineering column located in the centre of the tank and by the drive unit on the periphery of the tank. Its particular design allows a good adaptability of the equipment to the various irregularities of civil works.

DESCRIPTION:

Sweeping bridges mainly consist of the following elements

Drive group: Consisting on a fully enclosed carriage with driven wheel and drive wheel, in compliance with EC machine safety regulations, on which all the mechanisms are installed. The trolley is fixed to the mobile walkway by means of screws to minimize possible differences in the civil works.

Rotation table: This consists mainly of a large-diameter axial ball bearing capable of supporting high axial and tilting moment loads. Perpendicular to the bridge gangway, two oscillating ball bearing supports are provided to absorb any deficiencies in the peripheral running of the wheels.

Bridge Walkway: Constructed with UPN support beams, with latticework or with drawer-beam depending on the dimensions or according to the customer’s preferences. It is provided with protection railings built in tube and access ladder, if the installation requires it. All metal parts are treated with anti-corrosion treatment.

Surface/bottom sweeping scrapers: The structure of the sludge sweeping scrapers is fixed to the central turning gangway by means of tubular joints. The assembly system is simple and allows the scrapers to be adapted to any deviation in civil works. The support structure of the scrapers is made of tubular profiles.

Feeding cylinder or central bell: Suspended from the bridge, it surrounds the central column of the civil works and is designed to stabilize the flow of the liquid inlet. It is built in two or more halves and is fixed to the walkway by supports.

Perimeter spillway and deflector: The spillway and spillway are fixed to the perimeter channel by means of special clamps fixed by means of anchor bolts, which makes it very easy to level them both.

A set of rotating brushes can be supplied for cleaning channels and spillways driven by a gear motor.

We can build mobile suction bridges.