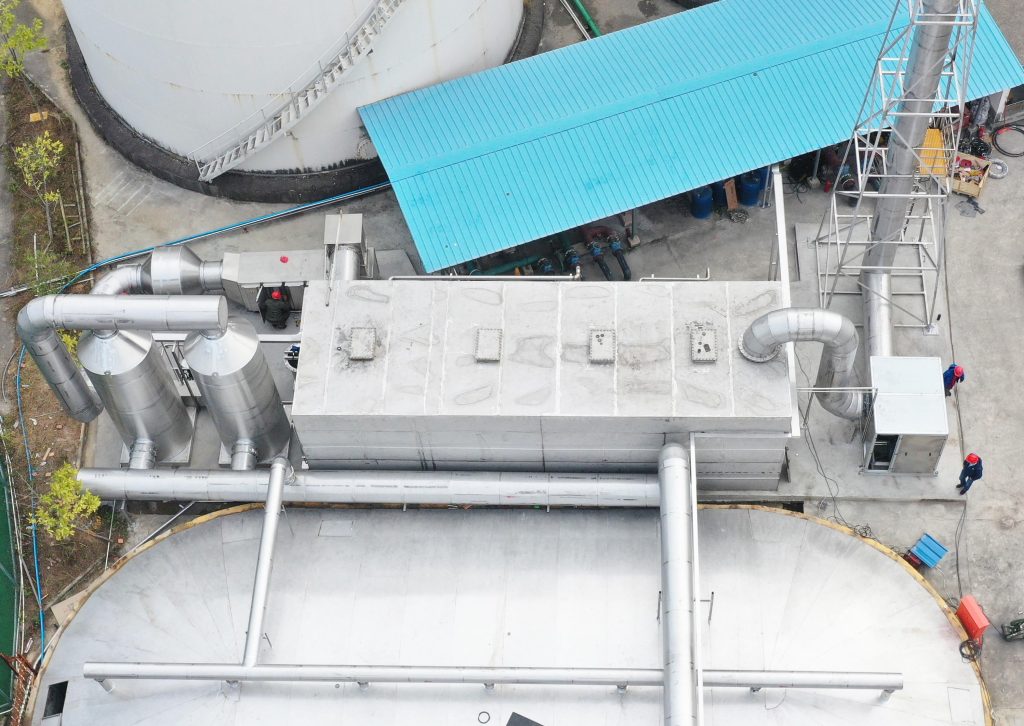

Biological Deodorization System

The equipment uses microorganisms to decompose odor, and is suitable for treating odor gas with complex composition and large flow rate. It has low operating cost and easy operation.

Description

Overview

Microbial treatment technology is very suitable for treating odorous gas with complex composition and large flow rate. Microorganisms treat odorous gases, mainly by inoculating deodorizing microorganisms on the carrier, and providing suitable humidity, PH value, oxygen, temperature and nutrients, etc., using microorganisms to realize the conversion of odorous substances, and adsorb, absorb and biologically odorous substances. into an odorless substance.

The biological deodorization system is composed of washing bed, biological filter bed, circulating spray system, discharge system, parameter control system and other parts. Equipment such as hydrogen gas transmitters, heaters, and glass rotameters require regular maintenance to make the system run more stably, safely and efficiently.

Working Principle

The biological deodorization system is mainly composed of exhaust system, biological filter and filler, spray system (circulating water system), etc.

The odorous gas is led by the fan to the primary air distribution area of the deodorization system through the pipeline system. The gas is processed through the spray packing area, the spray area, the secondary gas distribution area, and the biological packing area. The water-soluble substances in the gas are first transferred from the gas phase to the liquid phase, and are absorbed and degraded by different microbial populations. Nutrient solution, water and high-efficiency deodorizing microorganisms are pumped into the biological filter tank, and sprayed evenly on the top of the biological deodorization system;

the amount of atomized water spraying needs to be controlled during operation to ensure that the humidity in the biological filter tank is between 70% and 90%. , to maintain the fungal layer filler humidity between 60 and 80%. The amount of acid and alkali to be added is determined according to the pH value to ensure that the microorganisms survive in the appropriate acid-base range (PH: 3~8).

Scope of Application

It is suitable for industries such as printing plants, sewage plants, garbage stations, farms, slaughterhouses, petroleum and petrochemicals, processing plants, painting plants and leather processing plants.

Technical advantages

1. Biotechnology, environmental protection and hygiene, no secondary pollution;

2. It can treat exhaust gas containing multiple pollutants at the same time;

3. Strong impact resistance, when the exhaust gas concentration fluctuates between 3-1500ppm, it can work normally;

4. The treatment time is short, the efficiency is high, the purification can be completed in 5-10 seconds, and the overall efficiency can reach more than 95%;

5. Biological strains can be filmed at one time, with many strains and short inoculation time;

6. Low construction cost, low operating cost, and no need to add chemicals;

7. Made of glass fiber reinforced plastic/stainless steel, with beautiful appearance, strong corrosion resistance and long service life;

8. Using composite filter material, large surface area, good air permeability, no hardening, long service life;

9. Adopt PLC control, high degree of automation;

10. Double-layer structure, the interlayer is filled with thermal insulation material, suitable for operation in cold weather, and the inner layer is provided with an anti-corrosion layer.