Super Atomization Dissolved Air Flotation System

The equipment uses advanced third-generation dissolved air technology, Energy saving and high efficiency, Saving the cost of consumables, Unattended.

Description

Super Atomization Dissolved Air Flotation

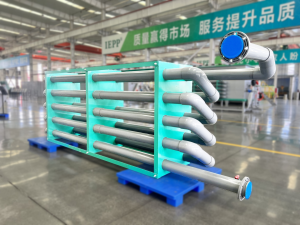

IEPP® SADAF UNIT DISPLAY:

![]()

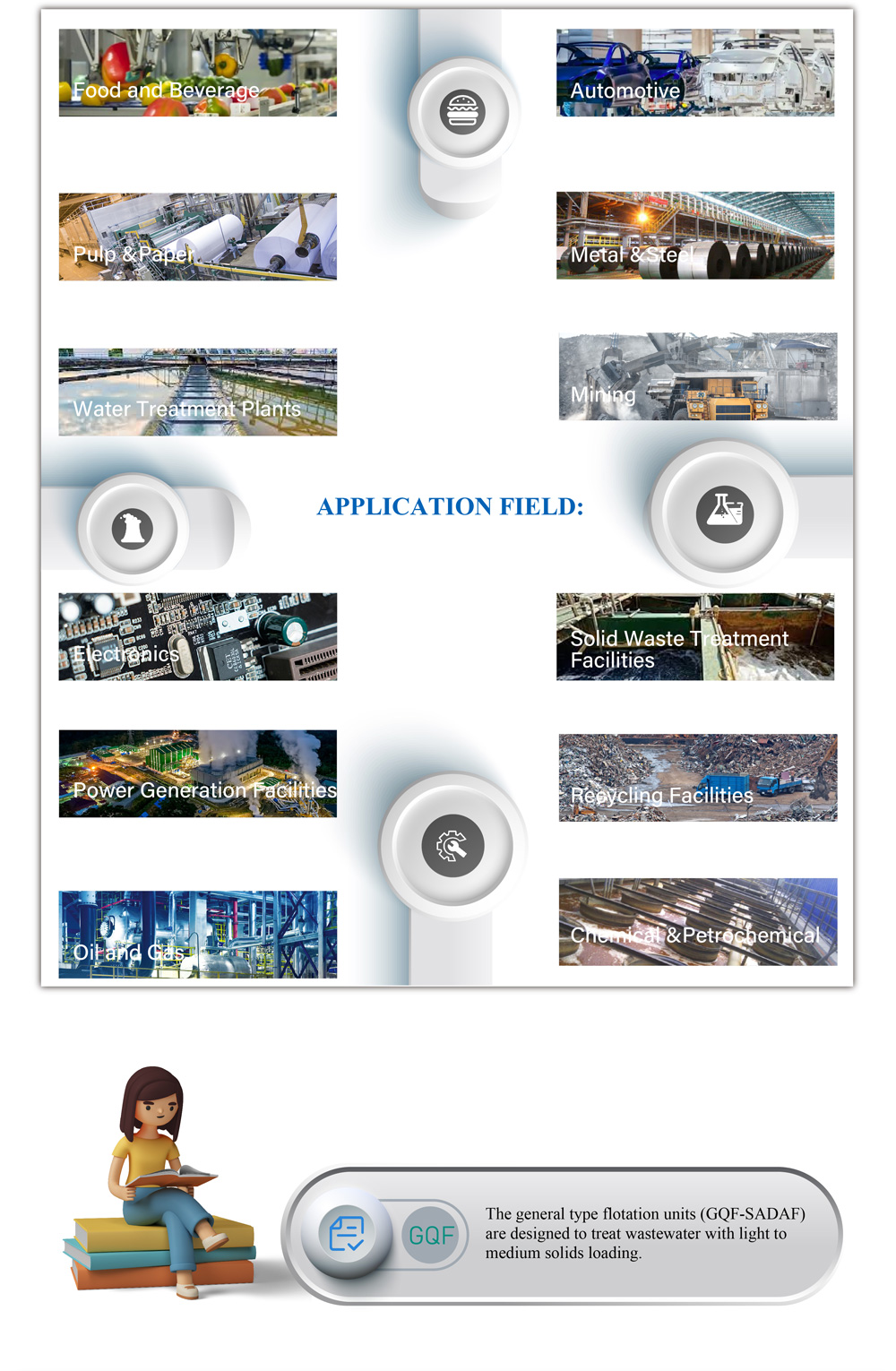

IEPP® Super Atomization Dissolved Air Flotation (SADAF) is a technology used ex- tensively for wastewater treatment in food plants, oil & gas, mining, pulp & paper many major industries and municipal wastewater plants.

It also has a very good fit for its use in clarification of drinking water treatment, especially for difficult to flocculate, low temperature, coloured waters, and waters subject to algae blooms. SADAF works extremely well for waters that have fats, oils, grease, and very fine particles.

_画板-1-1024x786.jpg)

The equipment can be used by itself as a clarifier, but when used with chemicals such as a coagulant and a flocculant, it becomes a physical&chemical process

ADVANTAGES OF THE IEPP® SADAF UNIT:

Super Atomization Dissolved Air Technology

Non-clogging Diffuser

Cyclone Mixing Flocculation Technology

Reverse Scraping and Thickening of Scum Technology

Cyclone Mixing Flocculation Technology

![]()

Flocculators are an essential component on all our SADAF compact systems. Our pipeline flocculators are characterized by the “in-line process principle”. In-line flocculator processes, such as coagulation, flocculation, demulsification, precipitation and pH control, can take place under highly controlled and well-defined conditions to obtain a uniform floc with excellent separation characteristics. This technology saves about 15% of chemical costs for our clients than using traditional dosing system of DAF every year.

![]()

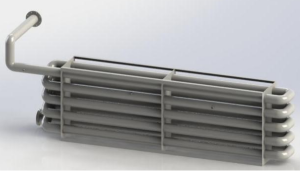

Non-Clogging Air-dissolved Water Releaser

![]()

The IEPP® SADAF uses a unique nanobubbles diffuser system, which is aunique patented technology of IEPP company. This technology ensures the stable performance of IEPPSADAF and realizes the goal that the DAF system can provide 24/7 continuous operation without blockage. The technology provides advanced technical advantages for our customers who have adopted our SADAF system, and also saves a lot of equipment maintenance costs and labor costs for our customers every year.

![]()

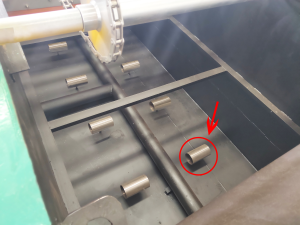

Super Atomized Dissolved Air Technology

![]()

Our unique super atomization air-dissolving technology: the liquid collides at high speed in a space that is only one-fifth the size of a traditional DAF air-dissolving tank to form tiny droplets of 10-20 nanometers. This increases the contact area of the air with the liquid, enabling the air to dissolve into the liquid within 0.6 seconds.

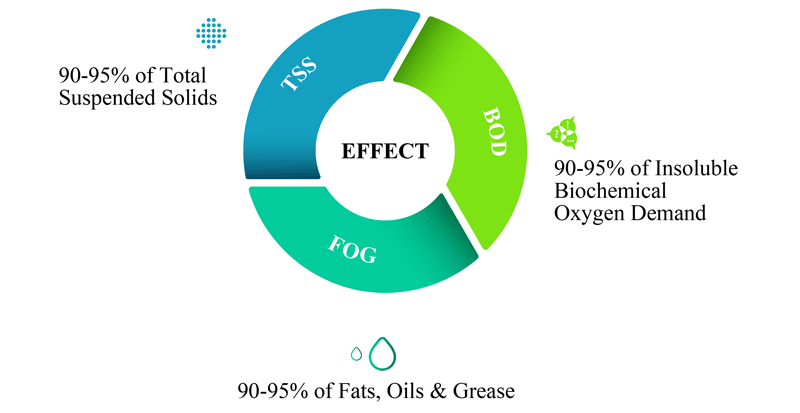

More efficient dissolved air efficiency ensures that customers who use SADAF will get ideal sewage treatment effect. The SADAF can remove more than 90% of TSS, more than 90% of insoluble COD, more than 90% of grease, and more than 90% of TP in the advanced treatment process.

![]()

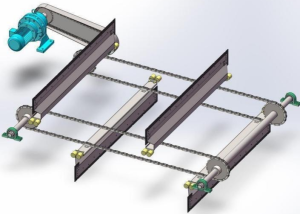

Reverse Scraping & Thickening of Scum Technology

![]()

Our company has made a lot of detailed improvements to the scum scraping system, including the use of safety nuts and all stainless steel material, which increases the stability and life of the SADAF system in outdoor operation. The reverse scraping system can minimize the water content in the scraped scum with minimal impact on the scum layer. This technical improvement can save a lot of costs for subsequent treatment of scum for customers using our SADAF every year.

![]()

A Properly Functioning IEPP® SADAF Will Remove:

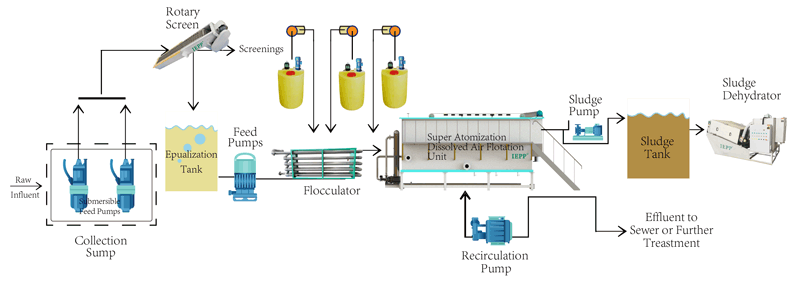

THE PROCESS OF SEWAGE TREATMENT:

A complete DAF system should includes:

- Influent flow equalization tank and mixing

- Feed pumps

- Polymer make down system

- Sludge pumping

- Pneumatic control panel

- Additional treatment steps as needed (sludge dewatering, biological, etc.)

- Screening to protect pumps

- Chemical feed (pH adjustment, coagulation, flocculation)

- Mix tanks or in-line pipe flocculation

- Sludge storage

- Central PLC control panel to run the complete system

- Compressed air supply