Wastewater treatment plant bulking and foaming

Wastewater treatment plants are facing major operational problems of bulking and foaming. Biological treatment process is to remove biodegradable pollutants from wastewater. Biodegradable constituents’ pollutants are metabolised by microorganism in the activated sludge. Biodegradable consuming rate is the deciding factor for oxidation and separation process performance of wastewater treatment. The poor separation problem is caused by bulking and foaming in the activated sludge treatment process. Therefore treatment plant design and operation requires better understanding of triggering condition and micro-organism for these problems. Because, correction actions are encompasses economics of parameter to be manipulated and efficiency of the operation due to chain effect of manipulation parameters.

Sludge bulking is a condition in which sludge become very light. It is increasing the volume with very low settling. Filamentous microorganism causes sludge bulking which interfere with settling of sludge. Number of activated sludge microorganism growth limiting elements in influent can benefit the filamentous microorganism. This condition occurs due to high SVI, low DO, low F/M ratio, nutrient deficiency and septic waste and low sludge concentration in return waste activated sludge. As a results sludge floats and over flow with effluent and discharge become poor quality.

Foaming is appearing on aeration tank or clarifier. Foam occurs at start-up of plant which is white colour and disappears once the process is established. However heavy and brown foam is more troublesome. It is occurring at the aeration tank that will migrate to clarifier. This foam may become thick and overflow at the clarifier. Principal cause of this type of foaming is due to presence of abundance of filamentous micro-organism such as Nocardia ssp, microthrix pacilla etc. Specifically, oil and grease, volatile fatty acid, low F/M ratio and long SRT and temperature mainly causes foaming due to presence of filamentous of Norcadia forms, Nostocoida limicola and type 1881 (Lindsey.B, etl 2011). Type of micro-organism presence is varying plant to plant that it does not require all above microorganism to cause foaming problem.

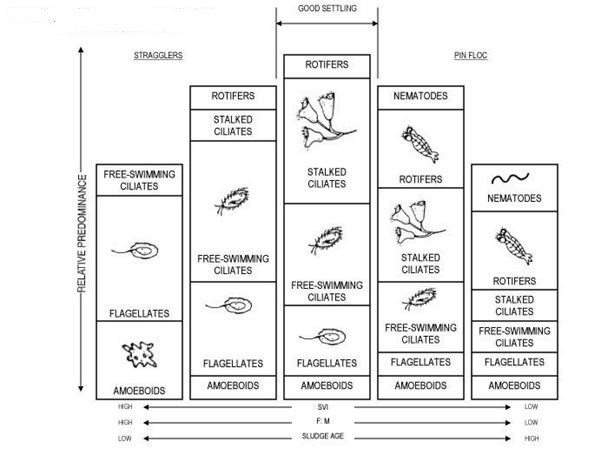

Regular microscopic protozoa population observation of activate sludge provides valuable information about condition of microbial population. The most widely occurring problem of sludge bulking can be identified by status of activated sludge. The protozoa population in the activated sludge wastewater, as shown in the Fig 01, can help to rapidly identify the operational condition due to cause of overloading, under aeration and low solid retention time. Temporarily heavy loaded (High F/M and low SRT) or start up activated sludge dominated with flagellate and amoebae. In the case of normal loading (good settling sludge) produces irregular floc with ciliate dominated activated sludge, however flagellate and amoebae presence in small number. In the case of light loading (Low F/M and high SRT), it produces pin floc activated sludge with ciliate presence in small number, however abundance of rotifer and nematode are presence in activated sludge.

Fig 1 Relative predominance of microorganism in the activated sludge

Observation of filamentous type in activated sludge provides early indication of bulking and foaming problem. The first step change on settling characteristic could be identified through microscopic examination of MLSS provide information on type of the filamentous or floc structure. This can be relating to dependence of bulking sludge. Many operational problems are attributed to characteristic of activated sludge floc. Mass of microorganism produced during activated sludge process agglomerate and flocculate and separate in the settling process. Activated sludge active population is heterotroph bacteria including pseudomonas, achromobacter, flavobacterium, alcaligenaceae, arthrobacter, citromonas as and zooglea with small presence of fungi and protozoa. The floc contains organic matter and inorganic particle from influent and extra cellular polymer that seems to promise the bio flocculation volatile matter. The floc are created from two steps process that bio flocculation (microstructure) and filamentous microorganism contribution (macro structure).

Macrostructure is formed basis of attach one to another that bio flocculation and agglomeration. The filamentous bacteria is playing major role on forming macro floc in the activated sludge process. The activated sludge is containing microstructure in the absence of filamentous bacteria. Microstructure floc is small and fragile that could cause pin floc. As a result, effluent contains large quantity of pin floc. Therefore filamentous bacteria help to form the larger and stable floc which is not break away at the aeration tank. It settles efficiently in the clarifier. The activated sludge needs good balance of filamentous bacteria and floc forming bacteria to provide the good settling. Sludge bulking occurs due to presence of too many filamentous microorganism, vice versa is very few filamentous microorganism results pin floc and poor settling. The observation of filamentous provides time for corrective action to be taken to minimise the operational problem associated with excessive growth of organism.

The filamentous microorganism appears in the system due to influence of variation in operational parameters. There are several parameters facilitate the growth of filamentous organism in activated sludge system such as low DO, High SRT, low F/M, SVI, temperature and pH and MLSS. It is reported that low DO could promote the bulking filamentous of Type 1701, S.natas and H.Hydrossis etc. There are two methods to control low DO bulking. One way of lowering DO is lowering F/M ratio which reduces requirement of DO. This can be achieved by increasing the RAS while reducing WAS. As results MLSS level increases in the aeration zone. There is a concern that concentration may exceed solid handling capacity of secondary clarifier that is the biggest constrain for this method. Second method is increasing DO level in the aeration zone which requires greater power input. As a results, operational cost increases. Therefore low DO conditions filamentous needs better alternative solution. It may be chlorination of RAS or on the aeration zone or effluent of aeration tank. Economic of control method selection must be addressed cost benefit analysis.

It is reported low F/M ratio could promote filamentous microorganism M.Parvicella, H.Hydrosis, Norcadia sp. Type 021N, 0041, 0675, 0092, 0581, 0803, etc. growth. The relationship cause and effect between F/M ratio and presence of filamentous microorganism is not completely understood. The specific growth of filamentous microorganism in the continuously fed completed mixing activated sludge system could produce poorly settling sludge compare to intermittently aerated system. Normal plant loads is between 0.2 to 0.5 kg BOD/MLSS.d to avoid the bulking problem. At higher F/M ratio, type 1701 or S.Natas may appear within the critical limit of DO. I have already discussed about changing F/M ratio better indicator is MLSS in the aeration zone. Matcalf and Eddy has recommended to have MLSS range of 1000 to 3000 mg/l in aeration zone. However, MLSS range in aeration zone depends on the type of the process used in the activated sludge system.

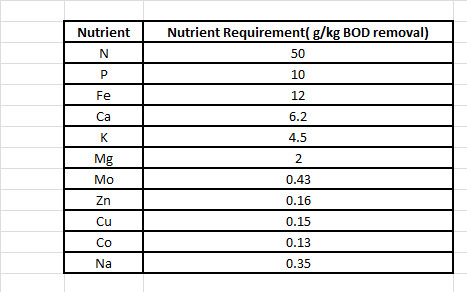

Nutrient deficiency could cause the filamentous growth such as Thiothrix Sp, S.natans, Nostocoida limicola II, Type 021N, H,Hydrosis, Type 0041 and 0675. Sufficient quantities of nitrogen and phosphorus nutrient needs in wastewater to minimise filamentous growth. However minimum amount of COD:N:P is usually assumed to be 100:5:1 in influent. The below table 1 shows the minimum nutrient requirement:

Table 1 : Nutrient requirements of activated sludge process (Grau, 1991)

Septic wastewater could contain the filamentous micro-organism such as Thiothrix sp and Beggiatoa and Type 021N. Thiothrix sp and Beggiatoa microorganism could possible to grow in the wastewater containing hydrogen sulphide which is reduced component of the influent of septic sewage. Further to that septic sewage contain fermentation product such as volatile fatty acids and reduces sulphur component (sulphides and theosulphate) can facilitate to grow different type of filamentous micro-organism. There are very good possibility for occurrence of filamentous microorganism in the septic sewage that can produce bulking sludge. Therefore it very important to evaluate microbial presence and characteristic of septic sewage feed to the wastewater treatment plant to minimise impact of filamentous micro-organism.

Every micro-organism has specific temperature range for growth. Micro-organism activity and growth is increasing with increase of temperature within the range to reach maximum. Further increases from maximum temperature of range, microorganism started to reduce growth abruptly. Therefore sludge population is varying with influent wastewater temperature. The filamentous, Microthrix Parvicella, grow very well at lower temperate (Dick, 2000). Bulking may occur during the winter season due to growth of this filamentous. The nutrient removal treatment plant with anoxic / or anaerobic, M.Parvicella cannot grow. However this micro-organism is capable of absorbing substances from the water phase in the absence of oxygen. Therefore nutrient removal plant degradation of fat and fatty acid could favour the environment for the growth of M.Parvicella. Therefore, influent with higher fat and fatty acid has to be bound by irreversible floc before taken up by M.Parvicella.

Wastewater treatment industry is dosing the chemical to control bulking of sludge. Normally chlorination is practised to control the filamentous growth through keeping SVI under control. This method is killing some of the required micro-organism; therefore consideration has to be taken to maintain the sludge population to encounter nitrification process requirements. It has been demonstrated that success is a strong function of effective chlorine distribution, exposure concentration, and exposure time. The chlorine dosing is reducing MLSS that could results non-compliances. The chlorination method of controlling filamentous growth increases the cost and difficult to comply with tighten and more comprehensive effluent current and future standard.

The selector option in the treatment seems to be good option to provide filamentous growth control and increasing capacity and reduce the cost of operation. The selector can be an anoxic selector or anaerobic selector or both, which is selected depend on the nutrient removal requirement. This is small volume of reactor mixing RAS and influent before aeration. Selector sizing is very crucial for leaking of readily biodegradable organic matter to aeration zone, results the growth of filamentous. It is better to have F/M ratio loading in the range of 0.8 to 1.2 kg BOD/ Kg MLSS/d with influent temperature more than 18 oC and 0.7 to 1.0 kg BOD/ Kg MLSS/d with influent temperature below 18 oC.

References

Lindsey Bergsven, Belinda Sturm, Abdu Durar, and Gerry Dickinson, After Over a Decade of Foaming, the Development of a Statistical Model Combined with Traditional Microscopy Provides Operating Guidelines. WEFTEC 2011

Grau.P, Criteria for nutrient balanced operation of activated sludge process. Water science and technology 24 (3-4), 251-258, 1991.

Matcalf & Eddy, Wastewater Engineering – Treatment and resource, 5th Edition.

Dick,H.E, Process control of activated sludge plants by microscopic investigation, 2000.