Decoding the Advanced Applications of Dissolved Air Flotation (DAF) in Wastewater Treatment

In the field of environmental engineering, wastewater treatment is a critical process for ensuring the protection of our water resources. Among the various technologies available, Dissolved Air Flotation (DAF) has emerged as a highly effective method for removing contaminants from wastewater. In this article, we will delve into the advanced applications of DAF in wastewater treatment, exploring its mechanisms, process optimization, and environmental benefits.

一、Understanding the Mechanisms of Dissolved Air Flotation (DAF):

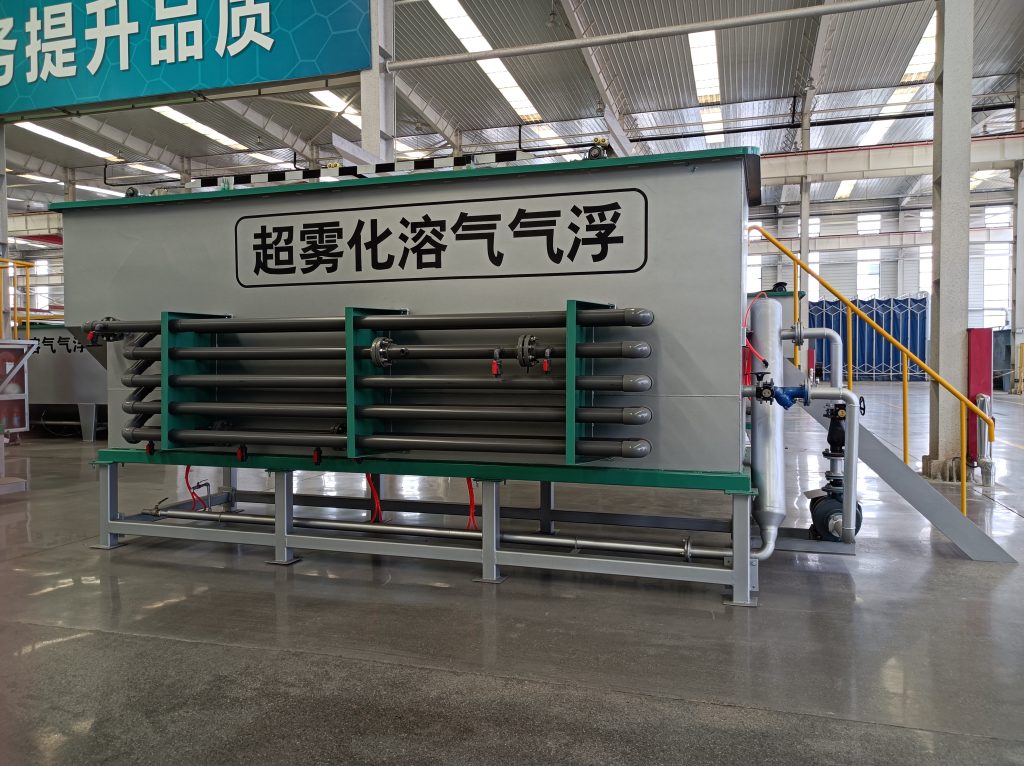

DAF is a physical-chemical process that utilizes the principle of air bubble attachment to separate and remove suspended solids, colloidal particles, and oils from wastewater. The process involves several key steps:

a. Coagulation and Flocculation: Coagulants are added to the wastewater to neutralize charges and promote the formation of larger particles called flocs. Flocculants are then introduced to aid in the agglomeration of smaller particles into larger, more easily removable flocs.

b. Saturation and Microbubble Generation: Air is dissolved under pressure in a saturator tank, creating supersaturated water. When the saturated water is released into the flotation tank, the sudden pressure drop causes the dissolved air to form microbubbles.

c. Mixing and Contact: The wastewater and microbubbles are mixed vigorously in the flotation tank, facilitating the attachment of microbubbles to the flocs and contaminants.

d. Flotation and Separation: The buoyant flocs and attached microbubbles rise to the surface of the flotation tank, forming a layer of foam or sludge, which is then skimmed off and removed.

e. Post-Treatment: The clarified water undergoes further treatment processes, such as filtration or disinfection, to meet the required effluent standards.

二、Process Optimization for Enhanced Efficiency:

To maximize the effectiveness of DAF, several parameters can be optimized:

a. Coagulant and Flocculant Selection: The choice of coagulants and flocculants depends on the wastewater composition and desired removal efficiency. Different chemicals have varying effects on coagulation kinetics and floc properties, thus requiring careful consideration.

b. pH Control: Adjusting the pH of the wastewater can influence coagulation and flocculation efficiency, as well as the stability and size of the formed flocs.

c. Mixing Intensity and Duration: Proper mixing ensures effective contact between flocs and microbubbles, enhancing attachment and flotation efficiency.

d. Microbubble Generation: Optimizing the saturator design, pressure, and bubble size distribution can improve the flotation performance of DAF systems.

e. Skimming and Sludge Removal: Efficient skimming mechanisms and proper sludge removal techniques contribute to maintaining optimal DAF operation and preventing clogging or foam carryover.

三、Advanced Applications of DAF in Wastewater Treatment:

a. Industrial Wastewater Treatment: DAF has proven to be highly effective in treating various industrial wastewater streams, including those from food processing, chemical manufacturing, paper mills, and oil refineries. It can efficiently remove suspended solids, oils, fats, and heavy metals, meeting stringent discharge regulations.

b. Municipal Wastewater Treatment: DAF has gained popularity in municipal wastewater treatment plants, particularly for primary and secondary clarification processes. It aids in the removal of organic matter, algae, and phosphorus, improving the efficiency of downstream treatment processes.

c. Water Reuse and Resource Recovery: DAF plays a vital role in water reuse applications, enabling the production of high-quality reclaimed water for irrigation, industrial useand other non-potable purposes. Additionally, DAF facilitates the recovery of valuable resources from wastewater, such as phosphorus and biomass, which can be used for fertilizer production or energy generation.

d. Treatment of Challenging Contaminants: DAF has shown promise in treating challenging contaminants, including microplastics, pharmaceuticals, and emerging pollutants. By effectively removing these substances, DAF contributes to minimizing their environmental impact and protecting aquatic ecosystems.

四、Environmental Benefits of DAF:

The advanced applications of DAF offer several environmental benefits:

a. Removal of Harmful Substances: DAF effectively removes suspended solids, organic matter, and pollutants from wastewater, preventing their release into receiving water bodies. This helps maintain water quality, safeguard aquatic life, and protect sensitive ecosystems.

b. Reduction of Nutrient Loads: DAF can aid in the removal of nutrients, such as nitrogen and phosphorus, mitigating eutrophication issues in water bodies and reducing the risk of harmful algal blooms.

c. Energy Efficiency: Compared to conventional sedimentation processes, DAF systems can achieve similar or better treatment efficiency with lower energy consumption. This contributes to overall energy savings and reduced carbon footprint.

d. Enhanced Sludge Dewatering: The sludge generated from DAF can undergo further treatment, such as mechanical dewatering or anaerobic digestion, to reduce its volume and improve its handling and disposal efficiency.

五、Future Developments and Innovations:

The field of DAF continues to evolve, with ongoing research and development efforts focusing on:

a. Advanced Flotation Technologies: Novel approaches, such as electroflotation, hybrid flotation systems, and the utilization of advanced materials for microbubble generation, are being explored to improve flotation efficiency and reduce operational costs.

b. Process Monitoring and Control: The integration of real-time monitoring, sensor technologies, and automation systems allows for better process control, optimization, and predictive maintenance of DAF units.

c. Resource Recovery: Researchers are exploring innovative methods to enhance the recovery of valuable resources, such as energy, nutrients, and chemicals, from DAF sludge, transforming it into a valuable byproduct.

Dissolved Air Flotation (DAF) has evolved into a versatile and advanced technology for wastewater treatment, with applications ranging from industrial wastewater treatment to municipal wastewater clarification and resource recovery. Through careful process optimization and continued research and innovation, DAF systems are poised to play a pivotal role in achieving sustainable water management, protecting the environment, and conserving valuable resources for future generations.