How does the multi-disc sprial sludge dewatering work?

Low energy consumption, small footprint, high cost effectiveness and wide range of applications make the screw sludge dewatering machine a dramatic rise in industrial wastewater treatment. High efficiency and automation are the unanimous praise of users. So how does it work? Here is a brief introduction to its working principle and main components.

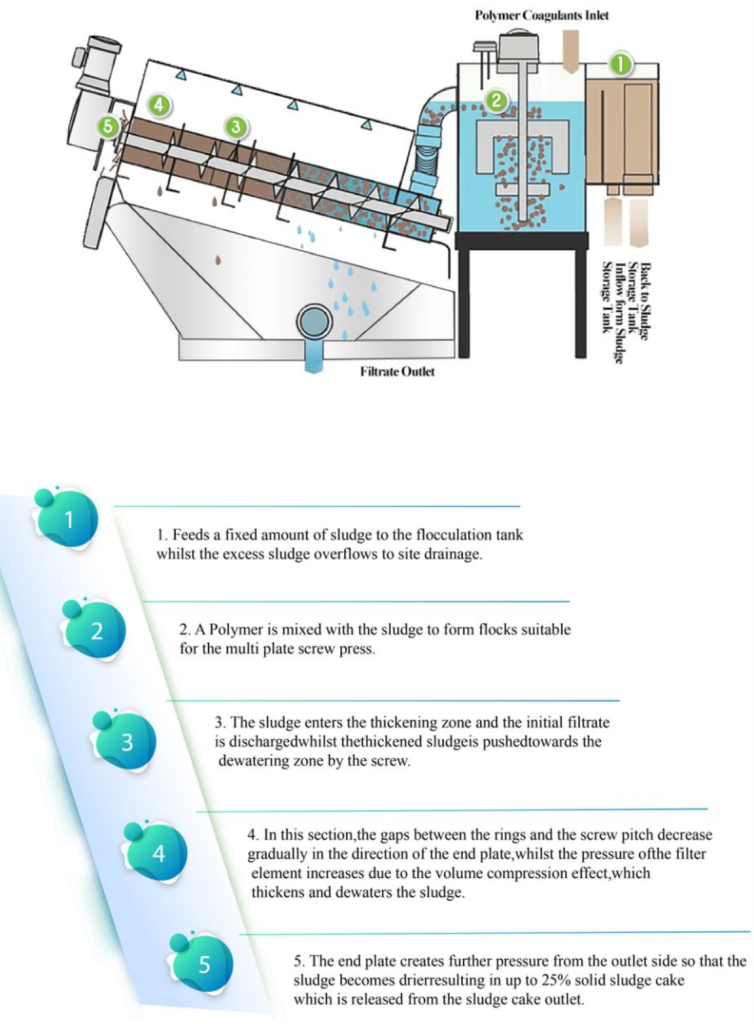

The dewatering body is formed by a screw axis with fixing and moving plates overlapping. As the inner diameter of screw axis is larger than the moving plate, the moving plate do the circular motion with the screw axis to prevent clogging. Space between the fixing and moving plates becomes smaller and smaller along the direction of mud discharge. After gravity concentration, the sludge is transported to the dehydration parts, it dewaters under the inner pressure of outlet back plate.

Sludge is fed via a sludge pump to the unit. And control of this pump is usually integrated in the Screw Press Sludge Dewatering Unit electric control cabinet.

Polymer solution is injected by a dosing pump prior the sludge entering flocculation tank that mixes polymer and sludge together.

The flocculated sludge mixture then flows into the screw body through feed tube. The screw shaft rotates, moving solids up the drum, the filtrate flows from the thickening zone into the filtrate collect base. With moving to dewatering zone, space between fixing and moving rings becomes smaller and smaller, pressure increases for further dewatering.

Dewatered sludge cake is discharged from the end of the dewatering unit. And here a conveyor can be applied to carry away the cakes. Control of the conveyor is also usually integrated into the Unit electric control cabinet.