Quickly troubleshooting a dissolved air flotation (DAF) system

A DAF is used to remove solids from wastewater using microbubbles and a chemical coagulant like a polymer. The solids are forced to the water’s surface and are removed using a mechanical scraper and then disposed of.

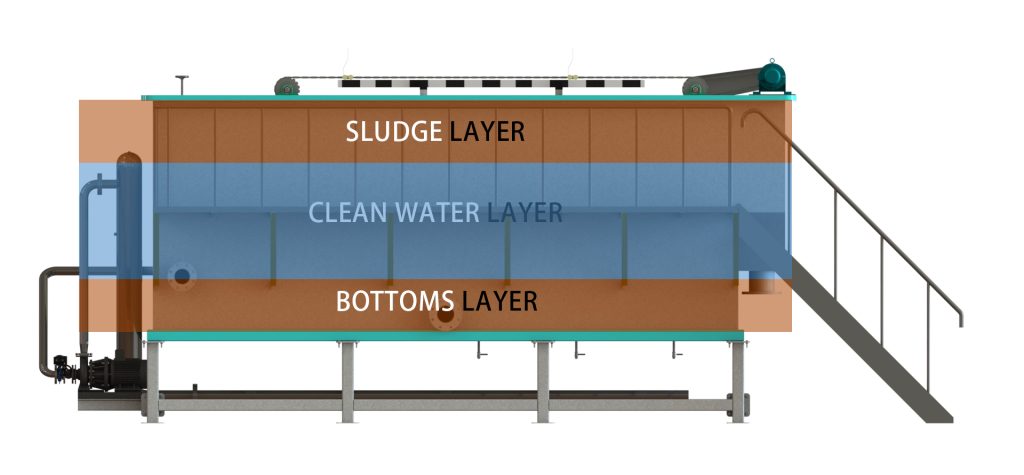

When the wastewater enters the DAF, it separates into three layers:

Our purpose is to get as many solids into the sludge layer as possible. So, we need to confirm that two critical processes are working correctly:

1: Is the DAF making microbubbles?

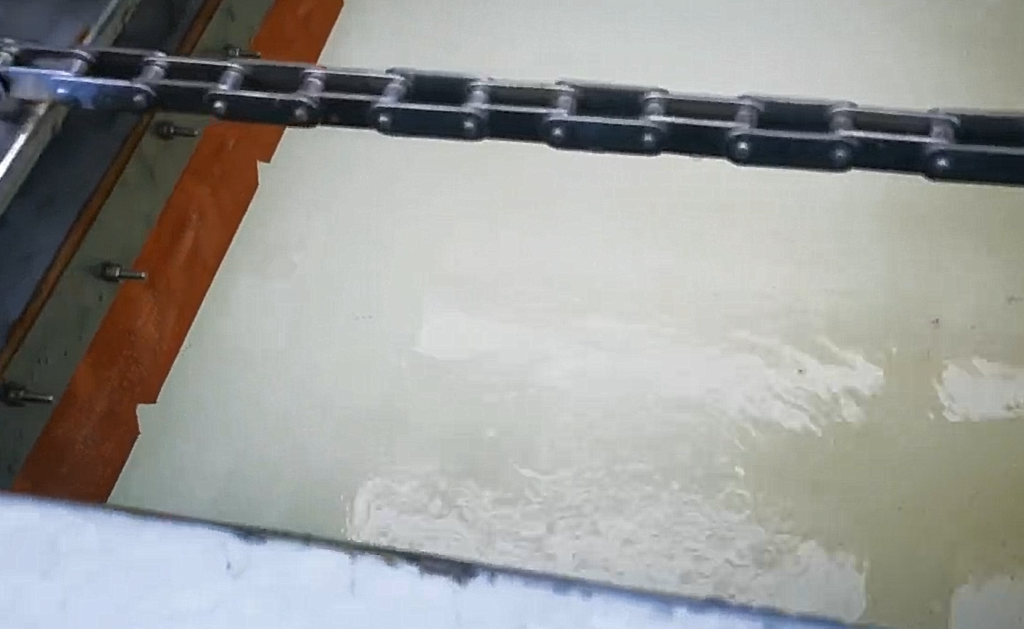

Look inside the DAF or take a sample off the microbubble diffusers to confirm the DAF is making “white water.” The water should look like milk; here is an example:

Poor microbubble situation:

Good microbubble situation:

If your DAF isn’t making whitewater, here are some things to check:

a. Check to see if your DAF pump is running: A pump can get kicked offline for several reasons or wasn’t turned back on after maintenance or downtime.

b. Check to see if your DAF pump is getting air: Oftentimes there will be a bad check valve or some other obstruction in the line preventing air from getting into the pump. Clear the line and confirm airflow.

c. Check back pressure on the DAF pump: Many DAF pumps need back pressure to produce microbubbles. Refer to the manual to see what is required.

d. Check the DAF diffusers: Make sure the DAF pump is evenly distributing the whitewater along the length of the DAF. Sometimes there will be closed or clogged valves preventing whitewater from getting into the systems.

e. Continually bleed bubbles from the white water vessel: It’s important to bleed off the white water vessel to prevent large and medium-sized bubbles from forming in DAF. The vessel can also build with air, which will eventually result in an air-locked DAF pump.

2: Are your chemicals working?

Dialing in your chemicals is the most challenging part of any DAF operation. Thousands of polymers behave differently under variant conditions. All polymers are sensitive to pH changes and it’s important to neutralize the waste stream before jar testing our operations. Finding the right polymer at the right dosage and injecting it at the correct time in the process can make or break an entire operation. We would suggest approaching multiple chemical suppliers to pick out three to five of the top-performing polymers. Remember, what works in the lab, won’t always work in the field.

Once you have your polymers, you will need to jar test them in the field to find an approximant dosage. The video below shows two different polymers (courtesy of ChemTreat); notice the one on the left reacts faster and creates a stronger flocc, but the one on the right captures more solids (notice the water quality) with weaker flocc. Which one is better? Only the operator can decide; it will come down to cost, performance, and the project objective.

Now that we have our polymers, how do you know they are working correctly in the DAF system? In the field, we have the operators go through a jar testing exercise.

First, we have them dose the polymer to create a “good”. We then have them do two more jar tests, one with an intentional under dosage and one with intentional overdosage. We have them OBSERVE the under and overdosage of polymer to know what to look for during operations.

When operating, here are the things we look for to get a hint that the polymers are working correctly:

a. Clear Water Over Effluent Weirs

b. “Popcorn” Thick Flocc Formation

c. Clear Water Pools Collecting on Top of the Sludge Blanket

3: Problems to Look For

Carry Over:

If the solids coming out of the effluent weirs is too much, this is typically caused by solids building in the bottoms layer. To fix the issue, clean your DAF frequently, at a longer duration.

Closing Thoughts

We hope this quick guide helps anyone trying to operate their DAF system. If you have more question in using the DAF, please contact us directly, we will answer your question as soon as possible. Our email address: iepp@cniepp.com.