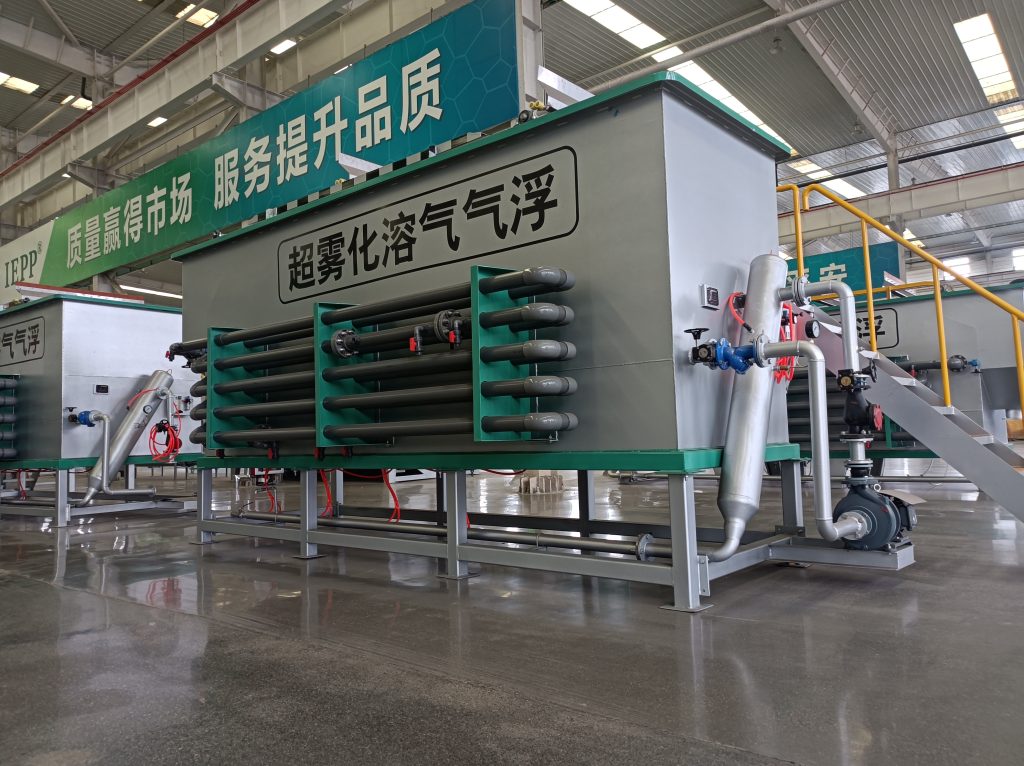

Wastewater treatment using dissolved air flotation process

process engineered water equipment Dissolved air flotation (DAF) is an effective way of treating wastewater treatment. It is important to know how water is treated because everyone uses water. This knowledge helps you understand how the water that you use is cleaned. This guide teaches you wastewater treatment using the DAF process.

Process

DAF process is achieved by removing solid suspensions from the wastewater using air. Air is dissolved into the wastewater under pressure. The air is then released at atmospheric pressure into a flotation tank.

The released water will then form bubbles which adhere to the suspended matter to float on top of the water. The suspended matter will then be filtered using a skimming device. Now that you have learned about the process, in summary, it is vital to get an in-depth understanding of the DAF process.

Chemical Mix Tank

The first part of DAF equipment, a type of process engineered water equipment, is a chemical mix tank. The feed water is poured into a chemical mix tank where a coagulant is added. Examples of coagulants include aluminum sulfate and ferric chloride.

The coagulant coagulates the feed water making the particles in wastewater to stick together for easy removal. The larger particles of dirt are referred to as flocs, which are easy to be captured by a belt filter.

However, the feed water is not always dosed with a coagulant. Thus, some DAF water treatment equipment lacks the chemical dosing system. After leaving the chemical feed station, the wastewater treatment moves into the flotation tank, which is the central part of the process engineered water equipment.

Air Drum

A portion of the wastewater is passed to the air drum, a small pressure vessel, where air is introduced. This is the point where the wastewater is saturated with air. The air-saturated water is then passed through a pressure reduction valve back to the flotation tank.

The air in the air-saturated water will be released as tiny bubbles to the rest of the wastewater, which had remained in the flotation tank. Bubbles form on the surface of the coagulated particles that are suspending on wastewater.

As bubbles form, they lift overcoming the force of gravity. This causes the suspended matter to float on the surface, forming a froth layer. The layer is then removed with a skimmer.

Industries that have specialized in water treatment have advanced process engineered water equipment that uses plate settler or lamella. A lamella is a packing material that provides more separation surface.

The plate settler clarifier enhances the separation efficiency of process engineered water equipment. Thus, industrial water treatment systems are also used to treat drinking water as the end product is usually perfectly clean.

Advantages Of DAF Systems

After learning how dissolved air flotation equipment works, it is vital to learn about its benefits.

Saves On Time

Surprisingly, dissolved air flotation requires just 3 minutes. The process will be done within this short time, and the water will be clean. Traditional rectangular DAF machines used to function for 20 to 30 minutes. However, the advanced circular type has a spiral scoop, which speeds that process up to 3 minutes.

This means that the equipment does not use enormous amounts of energy. At wastewater treatment plants pumping systems typically consume 10% to 15% of energy. Thus, using this aerobic treatment system helps to save on energy.

Ability To Remove A Wide Range Of Suspended Solids

One of the reasons why people use DAF water treatment equipment is that it removes a wide range of suspended solids. Thus, the water which will be released from the equipment will be free of any dirt.

Industries use it to remove large solids, whereas it is used in residents to remove small particles of dirt from water.

Clean Even Highly Colored Water

DAF water treatment system is also used to clean highly colored water, and thus it produces better water quality.

Using process engineered water equipment is effective when cleaning water. DAF system, as an example of process engineered water equipment, has benefited the water cleaning industry.